Research & Development

on Dyno and Racetrack

Limited Mappack based petrol tuningfiles

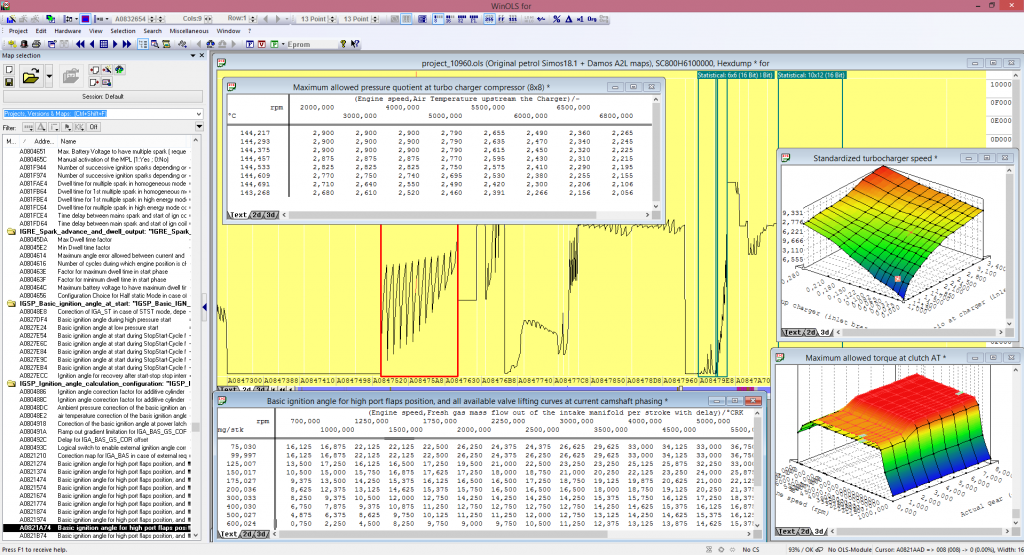

We modify all engines in a way that the combustion is improved. We do not simply increase turbo pressure by 30% and hope it will work out fine, but we meticulously test all adjustments for both safety and performance. It is very important to understand how the ECU works and what the exact factors, offsets, and axis are in the map of a file. This way we can modify the ECU correctly.

In order to know this data, we need to compare your file with our Limited Mappack and Funktionsrahmen. For most ECU, we have this data available. Example of Limited Mappack Feeling more power during a test drive or measuring it on a dyno is no guarantee that the engine of your vehicle is 7 optimally adjusted. In fact, in most cases, the changes are completely illogical according to the manufacturer, inefficient, and harmful to your engine.

ECUfiles petrol tuning strategy:

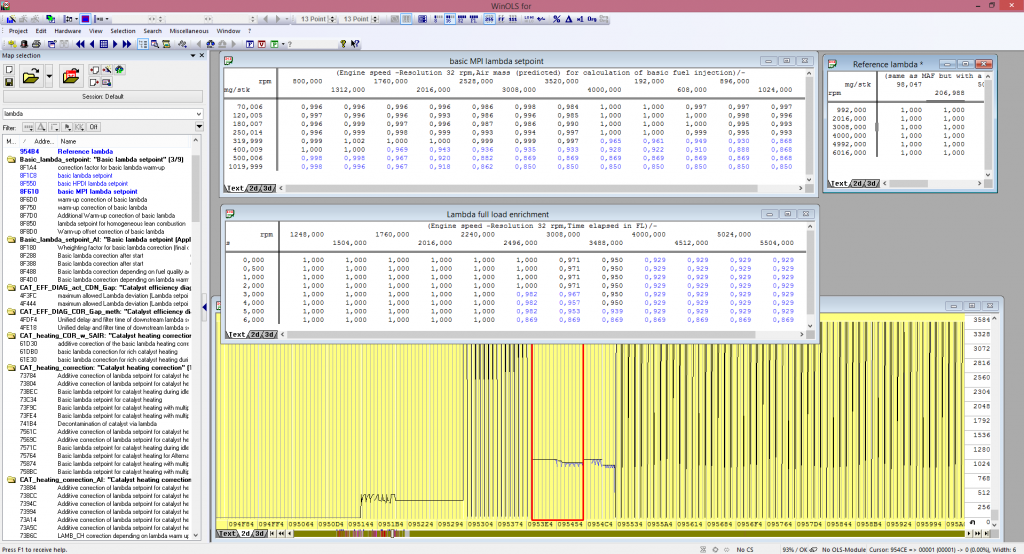

Firstly, we modify the lambda maps and make sure the mixture in all air loads and the full rpm range is perfect. During development, we compare data logs and dyno runs of the original engine to the modified engine and check if our commands are made correctly. If not, we modify until the lambda is perfect. In some cases, it is needed to rework the fuel maps to make sure the requested and actual lambda match.

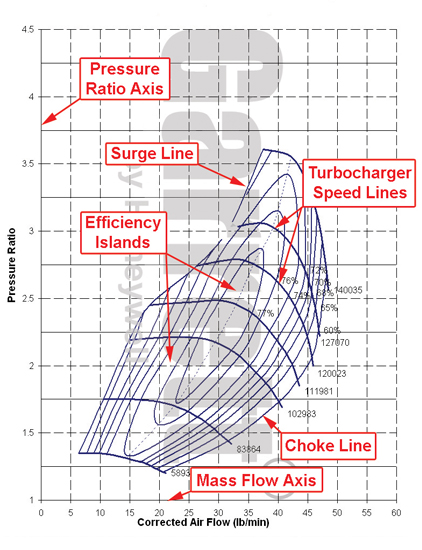

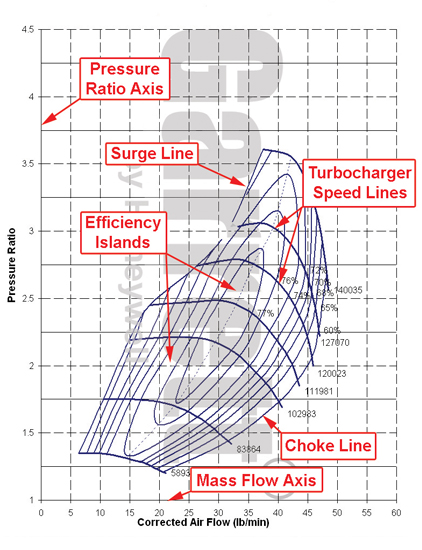

Then we modify the request of torque and air load in the pedal maps. After that torque and air load limiters for component protection are increased. The air load turbo limiters are only increased minimally and only in the efficiency island of the turbo to prevent surge and choke. On the datalog, we can see the requested and actual given boost pressure. We make sure these values match as much as possible to make sure the software is balanced.

In some cases, we need to modify and extend turbo PID control and wastegate maps including the axis to make sure the requested air load is supported in these maps. To keep the torque monitoring system working correctly we also modify these maps in reference to our requested torque and air load. In the case of a fuel rail system, we add minimum pressure to the fuel rail for a slightly improved spray pattern.

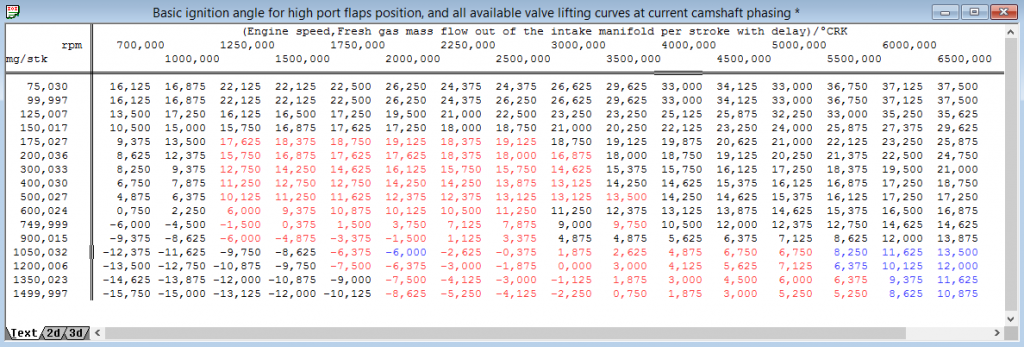

When air and fuel are set correctly we optimize ignition in our tuning files. The modification of ignition is based on the sort of fuel, petrol or gas, fuel quality, RON/MON/AKI values, outside conditions, the modified lambda AFR values, and compressor ratio. With ignition, it is important to prevent knock and detonation. So we retard the timing, in case of a higher compression ratio. But in many cases, it is possible to even advance the ignition. When this happens the safety margin in degrees of the crankshaft to prevent knock is too high for optimum combustion. So if we advance then, the combustion will be more efficient. The downside of this is that it causes higher NOX values.

The profit is better efficiency. When developing a tuning file we can perfectly see in data logs, if the ignition is optimal or not. When ECU is retarding the base ignition, this is a clear sign of too advanced ignition. But of course, the best way is to datalog the knock sensors on all cylinders.

example compressormap including explanation

Temperature limiters on oil, fuel, coolant, intake air, and exhaust gas temperature are in many cases not deleted in our tuning file for original parts. They are just slightly modified to prevent them from cutting power too early. The combination of all these small modifications gives you a high-quality safe tuning file for original parts, which gives great power and is very well balanced. Of course in many places, there are many more modifications we make in order to make a car run well and consistently.

This is just a brief explanation of what we do to an engine. As you can see a good petrol tuning file is dependent on many factors. That’s why petrol engine tuning is always customized and the given specifications are just an indication of performance gains. One overall comment, we need to make is that this is just one strategy of tuning.

There are different strategies possible. We tend to keep this specific strategy because it is closest to how the factory would do it. However, there are some cases where we change strategy because too little information is available about the ECU, or in case a different strategy just gives better results. optional:

- Removal of Cat control function, second lambda sensor off

- Stage 2 tuningfile for mechanical modification to inlet or outlet

- Stage 3 tuningfile for mechanical modification to compressor ratio

- Pop and bang

- Map switching

- Higher Vmax

- Higher Nmax – RPM

- Optimization for GAS – LPI – LPG

- Removal of DTC

- Modification of gearbox

Limited Mappack based diesel tuningfiles

The engine of your vehicle will be modified in such a way that the combustion will be greatly improved. We do not just increase the turbo or injection by 10 percent and hope it will be alright.

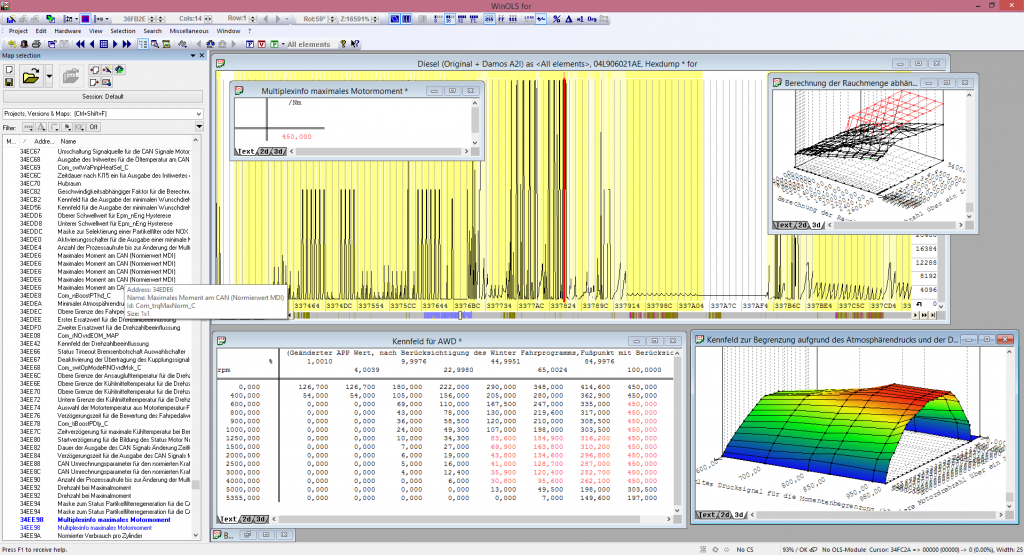

It is very important to understand how the ECU works and what the exact factors, offsets, and axis are in the map of a file. This way you can modify the ECU correctly. In order to know this data, we need to compare your file to our Limited Mappack and Funktionsrahmen. Feeling more power during a test drive or measuring it on a dyno is no guarantee that the engine of your model is optimally adjusted. In fact, in most cases, the changes are completely illogical according to the manufacturer, inefficient, and harmful to your engine.

ECUfiles diesel tuning strategy:

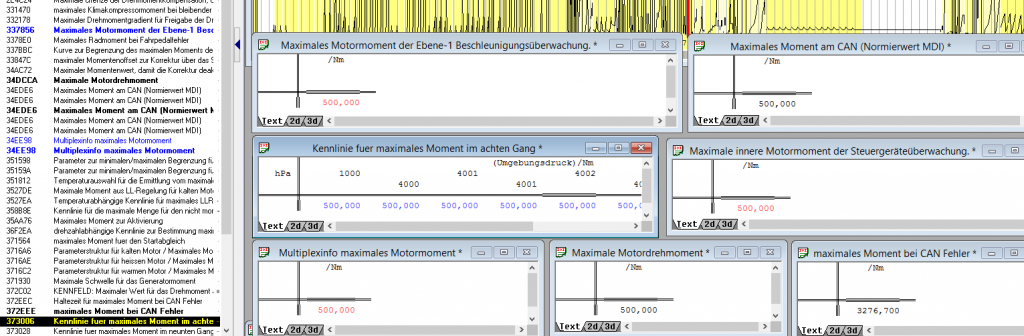

Firstly, we modify the request of fuel or torque in the pedal maps. Then the torque limiters for component protection, including the single value torque limits. When data logging and during a dyno run we can perfectly see if we have put all limiters at the correct settings.

We check if the smoke limiter is set high enough for the requested torque. If not, we modify it, but not too much, to prevent it from smoking. We add minimum pressure to the fuel rail for a slightly improved spray pattern. In some cases, we need to extend the NM conversion maps including the axis to allow enough torque to be converted into realistic milligrams of fuel injection.

In some cases, we change the values in the injector map too, but we try to keep this to a minimum. In order to optimize combustion, we modify the start of injection. The downside of this is that it causes higher NOX values. The profit is better efficiency. We modify turbo pressure to make sure the mixture stays correct. Turbo pressure is only increased minimally and only in the efficiency island of the turbo the prevent surge and choke.

In some cases, we need to extend the axis and allow higher values in the turbo maps to allow more boost at a higher specific injection quantity.

Then we perform data logging and check what lambda and fuel trims are doing. We use this data to correct the lambda maps. Temperature limiters on oil, fuel, coolant, and intake air. Exhaust gas temperatures are in many cases not deleted in our tuning file for original parts, they are just slightly modified to prevent them from cutting power too early.

The combination of all these small modifications gives you a high-quality safe tuning file for original parts, which gives great power and is very well balanced. Of course, there are many more modifications we make in order to make a car run well and consistently. This is just a brief explanation of what we do to an engine. As you can see a good diesel tuning file is dependent on many factors.

That’s why diesel engine tuning is always customized and the given specifications are just an indication of performance gains One overall comment we need to make is that this is just one strategy of tuning.

There are different strategies possible. We tend to keep this specific strategy because it is closest to how the factory would do it. However there are some cases where we change strategy because too little information is available about the ECU, or in case a different strategy just gives better results. optional:

- Stage 2 tuningfile for mechanical modification to inlet or outlet

- Removal of Vmax

- Removal of DPF

- Removal of EGR

- Removal of Adblue

- Stage 3 tuningfile for mechanical modification to compressor ratio

- Removal of DTC

- Removal of Flapps

- Removal of NOX sensor

- Modification of gearbox

Tuning file service.

This is how it works

Find out more in our Customer Portal

Register for free. See detailed specifications and download tuning files.

One time buyer? Start right away, no registration needed.