How Does A Turbocharger Work And How To Keep It Working Properly

In the past, turbochargers were used only in sports cars. Now, turbochargers in standard passenger cars with both diesel and gasoline engines are not a surprise. We will explain how turbochargers work and how they are built.

How does a turbocharger work?

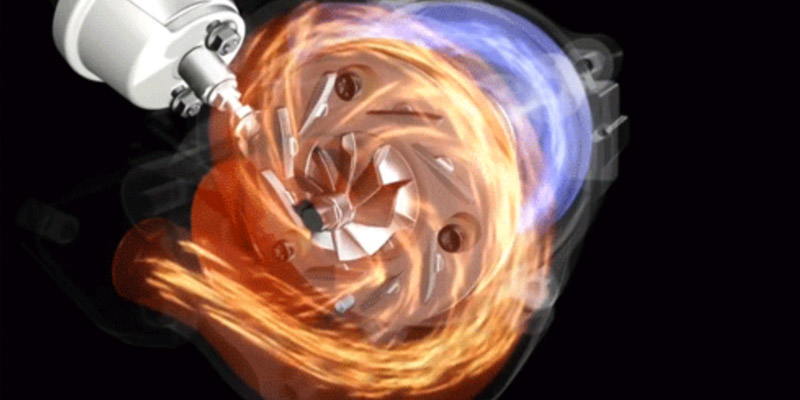

The principle is very simple. A turbocharger has 2 special impellers, which are located on a common shaft. The first rotor is mounted in the exhaust system and is powered by exhaust gases that come out of the engine. The second rotor can be found in the intake pipe. This specific rotor has a chance to function through contoured blades,  through those blades a turbocharger injects air into the drive unit. It injects air with the pressure which is much higher than the pressure of the atmospheric air. This is why an engine with turbocharger works more efficiently.

through those blades a turbocharger injects air into the drive unit. It injects air with the pressure which is much higher than the pressure of the atmospheric air. This is why an engine with turbocharger works more efficiently.

Construction of a turbocharger is one important key, but why a turbocharger provides such and no other effects?

You need to know that power depends on the amount of fuel burned in a given time unit. To make this happen, oxygen must be supplied to the engine, and to get into details it is known that 14 kilograms of oxygen is needed to burn a kilo of fuel. If more air is provided to the engine then we can obtain more combustion at identical revs and the same capacity of the power unit. Also, it’s important that in this process, the air-fuel mixture burns more efficiently, which causes less harmful substances to enter the atmosphere.

A turbocharger is a simple and efficient device, but not entirely free from defects. One of the defects is sensitivity to incorrect operation. You may wonder how to make turbocharger in your car work as long as possible. One of the most important rules is to keep your car’s engine clean. Which means that you regularly should replace your filters. If you don’t change filters a deposition of contaminants can lead to a change in balance, which is bad for bearings. Very important also is changing regularly engine’s oil. Changes in viscosity, quality, and oil grade have a negative impact on the engine and its components – including turbochargers.

Also, the mode of operation of the car witch a turbocharger is very important. you should avoid, rapid starts just after starting the engine when it is cold. It is important to know that just after a start the oil does not reach various nooks of the engine. When we drive intensively just after the car starts, we expose the bearings to improper lubrication, which may cause a decrease in their durability. While driving, it is worth driving in such a way that the tachometer shows medium and high revs.

Also, turning off the engine has a major impact on turbocharger durability. We recommend that you wait at least a few seconds before turning off the engine to gradually reduce the turbine speed because just after the engine ends, the oil pump also stops working. The effect of it is that it does not supply oil to the bearings of the turbine, which rotor is still rotating!

And it is the lack of lubrication that is one of the most common faults in turbochargers. Also, the steering controls for steering wheel deflection, oil leaks, or malfunctioning of the vacuum controller often occur. It also happens that the rotor breaks down, whose notched or bent blades not only do not generate the right pressure but can also lead to faster wear of the bearings due to a lack of proper balance.

SPECIFICATIONS

Mass Flow Rate

Mass flow rate is the mass of air flowing through the engine and turbocharger compressor calculated by a given period of time. Usually, it is expressed as pounds per minute (lb/min). The mass flow can be measured physically and it is important to estimate the mass flow to choose the proper turbo. Usually, people use the volumetric flow rate instead of the mass flow rate. The volumetric flow rate is expressed as CFM or ft3/min (cubic feet per minute). This can be converted to Mass Flow Rate by multiplying by the air density.

In a general rule, turbocharged gasoline engines generate 9.5-10.5 horsepower for each lb/min of airflow. An engine with a target 400 hp will require 36-44 lb/min of airflow to achieve this result. Based on this general rule you can calculate how much is your car’s flow rate and choose the right turbocharger.

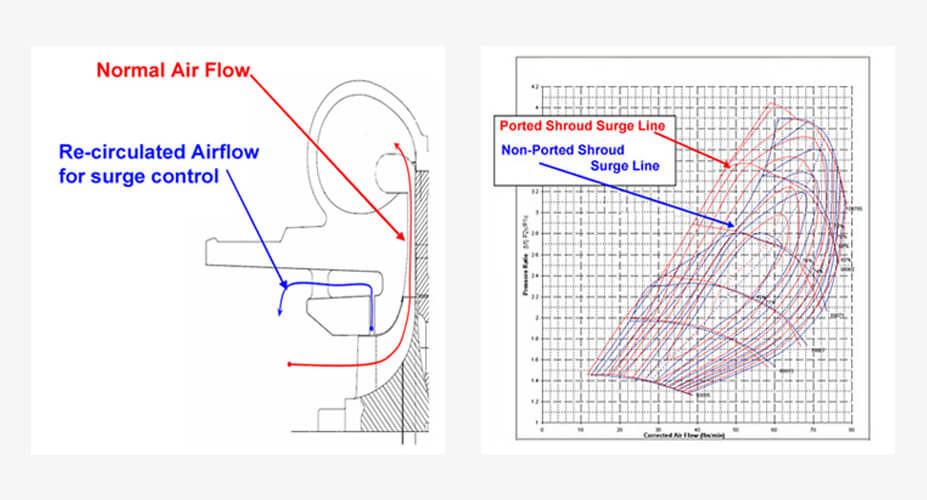

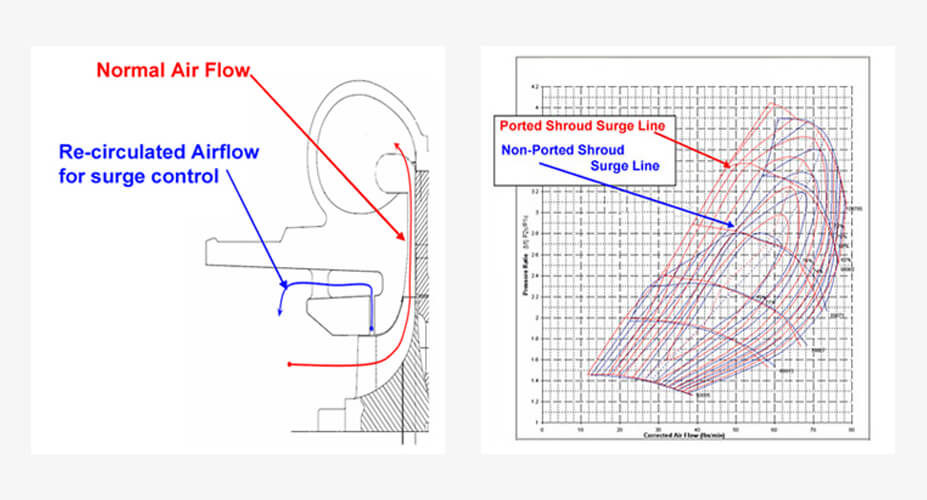

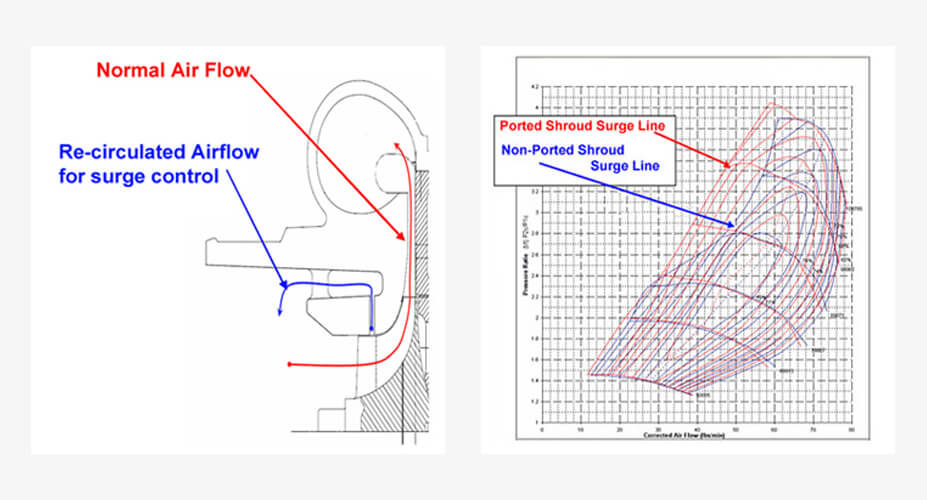

Surge Line

A surge is a left boundary of the compressor map. You can see flow instability to the left of this line. There are 2 types of the surge. First is a surge under load and the second surge is when the throttle is quickly closed after boosting. A ported shroud compressor is a feature that is incorporated into the compressor housing. A ported shroud compressor can move the surge line further to the left by allowing some airflow to exit the wheel.

Choke Line

A choke line is on the right side of the compressor map. The choke line is typically defined by the point where the efficiency drops below 58%. The turbo speed will also be approaching or exceeding the allowable limit. The larger compressor is needed when planning operations beyond the limit.

Turbo Speed Lines

Constant turbo speed is shown as Turbo Speed Lines. As turbo speed increases, the pressure ratio increases and/or mass flow increases. Once a compressor is operating past the choke limit, turbo speed increases very quickly.